-

![Médiathèque Robert Desnos]()

Médiathèque Robert Desnos

The Mastery of Materials

-

![Childcare Center Tourette-Levens]()

Childcare Center Tourette-Levens

The Mastery of Materials

-

![Gare RER Porte Maillot]()

Gare RER Porte Maillot

The Mastery of Materials

-

![Le Toison d'Or]()

Le Toison d'Or

The Mastery of Materials

-

![Lillénium]()

Lillénium

The Mastery of Materials

-

![Palais de Justice Anvers]()

Palais de Justice Anvers

The Mastery of Materials

-

![Châtellerault School Complex]()

Châtellerault School Complex

The Mastery of Materials

-

![Bertrand de Born Swimming Pool]()

Bertrand de Born Swimming Pool

The Mastery of Materials

-

For over 30 years, Betsinor has produced glass fibre reinforced concrete panels for outstanding projects. Unique is the Betsinor mark of quality. The product is of the highest standards, that speaks for itself, under permanent supervision within our own laboratory.

Of equal importance is the team behind this: highly qualified and experienced team members ensure that also engineering, installation and logistics are of a high level.

-

It seems a paradox, but a hard surface material like concrete is excellent for sound reducing applications. Even very thin panels have adequate mass to block sound. Shape and texture contribute to the distortion of sound, bringing great results.

By perforations in the concrete and sound absorbing materials at the rear, sound can be mouffled als well. In train and subway stations architecture meets functionality

Image: acoustics

-

Sounds much better dan sun blinds. A brise soleil by Betsinor looks better too. Ultra-high performance concrete makes it possible to build extremely thin slats.

As the material of the slats is the same as that of the cladding, a natural, homogeneous effect is achieved.

The brise soleil has additional functionality when they can be pivoted. Vivid and functional.

Image: brise-soleil

-

You want to design the façade you always have been dreaming of without making concessions.

With Betsinor Glassfibre reinforced concrete you have full freedom of design in your hands. You can model according to your ideal picture.

Shape, texture, colour, dimensions - you are in control.

Image: facades

-

Image: light

-

The best possible result can be achieved when all aspects related to the façade are identified and a balanced concept is realized.

The priority per subject can vary per project. The Betsinor Concrete Concept is a designer’s tool that helps you to realise best possible result.

![Concrete Concept]()

Concrete Concept

-

![Concrete Concept]()

Concrete Concept

Concrete Concept is a design tool that ensures that the optimum result for the facade can be achieved. The starting points from the design are first mapped out. The outcome is evaluated and subsequently points for improvement are made clear. If these are addressed, you have the best conceivable facade.

Latest Achievements, Iconic Projects

-

![Complete Freedom]()

Complete Freedom

You want to design the façade you always have been dreaming of without making concessions.

With Betsinor Glassfibre reinforced concrete you have full freedom of design in your hands. You can model according to your ideal picture.

Shape, texture, colour, dimensions - you are in control.

-

![Freedom]()

Freedom

-

Image: Playing With Light

-

There are virtually no limits with Betsinor. As long as we can demould it, you can select any texture.

Even a texture of just a few millimetres will bring special effects

You can choose from hundreds of standard patterns. Or design your own texture.

A small prototype mock-up will ensure the right result. Service!

![Textures]()

Textures

-

Image: Texture Details

-

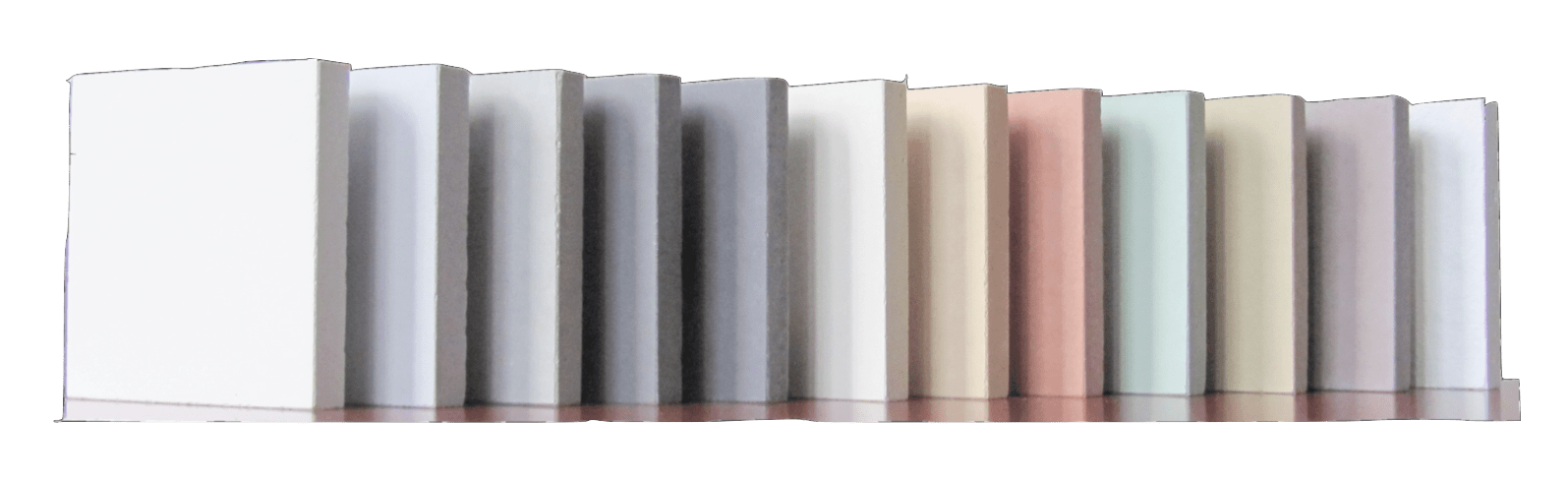

Image: Concrete Colours

Glass Fiber Reinforced Concrete gives you freedom in design, form and execution.

-

Case Study

A landmark building is demolished. The architect wanted to connect the new building to the historic context and got the idea to have the debris of the old building to become part of the texture in the new building’s facade. A small mock up has been made, used to make a elastomere mould. This became the mould used for making the panels. The colour of the concrete has been linked to those of the adjacent buildings in the urban area.

![Case Study]()

Case Study

![Case Study]()

Case Study

![Case Study]()

Case Study

![Case Study]()

Case Study

Incorporate any colour you can imagine using Glass Fiber Reinforced Concrete.

-

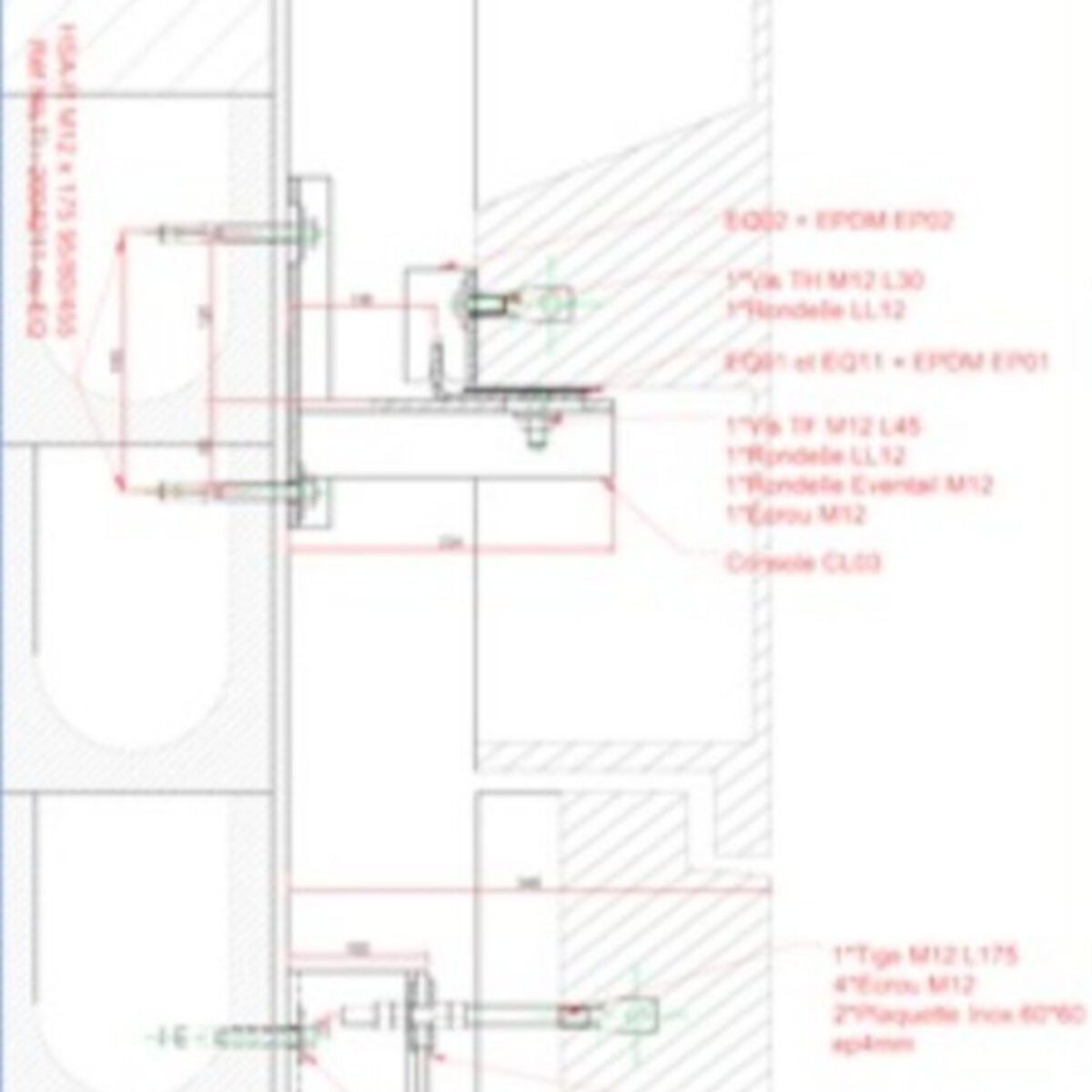

Pay close attention to the details of your facade. The specification should include all relevant information, ensuring a method that conforms. We gladly cooperate with you to find the best possible solutions, taking the budget into consideration. There is no compromise in quality.

![Correct Design Detailing]()

Correct Design Detailing

-

correct

![Constructive Element Colors]()

Constructive Element Colors

incorrect![Constructive Element Colors]()

Constructive Element Colors

-

correct

![Unequal Joint Widths]()

Unequal Joint Widths

incorrect![Equal Joint Widths]()

Equal Joint Widths

The door of this gas cabinet is covered with a concrete panel.

The difference in seam width has been created to meet the ventilation requirements of the network operator.

Detail your designs in such a way that the joint width is the same. And ensure that the sub-frame is painted in a color matching the panels.

Betsinor is concrete. Both in material and in their rock-solid execution of successful projects.

-

The Romans have discovered the unique advantages of this material way back. Often we are asked about the properties of our concrete. Well, because it is real concrete, they are the same as any concrete. However, thanks to a better cement to water ratio and the use of polymer, they are superior to regular concrete.

![Concrete Components]()

Concrete Components

-

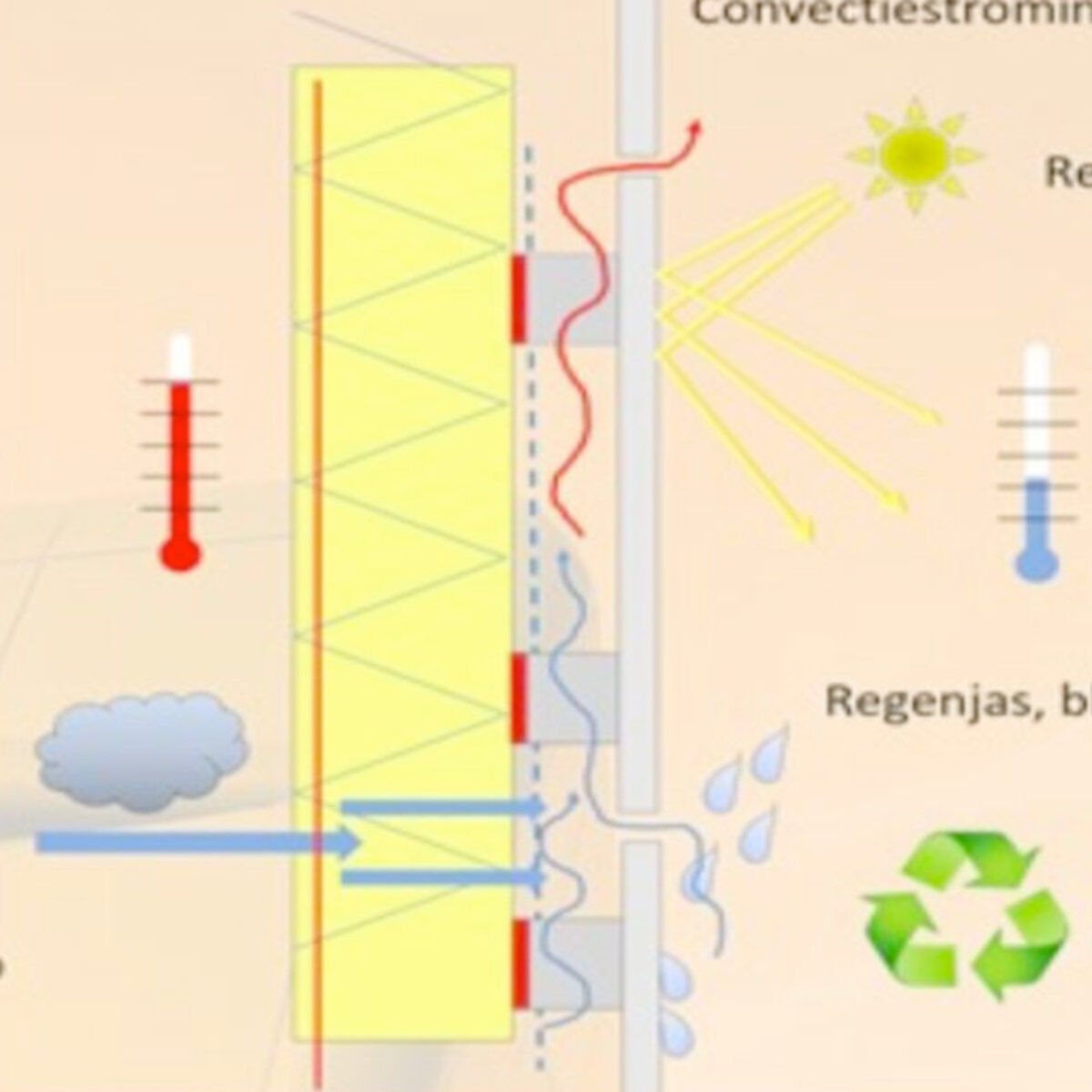

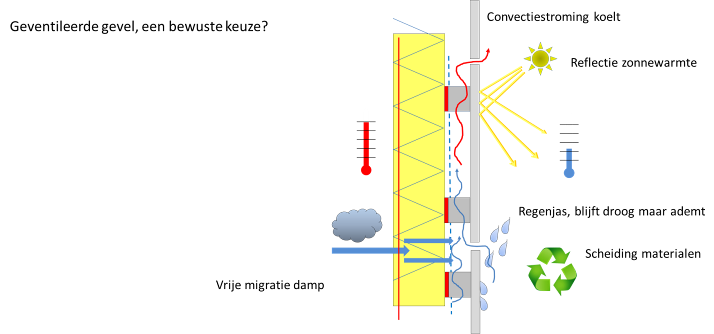

![Ventilated Facades]()

Ventilated Facades

Our panels are commonly used for rainscreen cladding. This type of cladding offers many advantages compared to a more traditional façades. In short, it presents better conditions within the building in combination with a light weight construction. This type of façade is common in countries with a high level of sun radiation and temperatures. In these areas we learn to appreciate its benefits more and more.

-

Here Betsinor makes the difference with other manufacturers of Glassfibre reinforced concrete. Our products are tested to withstand all kinds of loads and impact. Our production is under constant supervision by governing bodies. The result is a fully certified product. Betsinor is the only manufacturer of Glassfibre reinforced concrete having CSTB certification, providing reassurance in quality and reliability.

![Safety]()

Safety

-

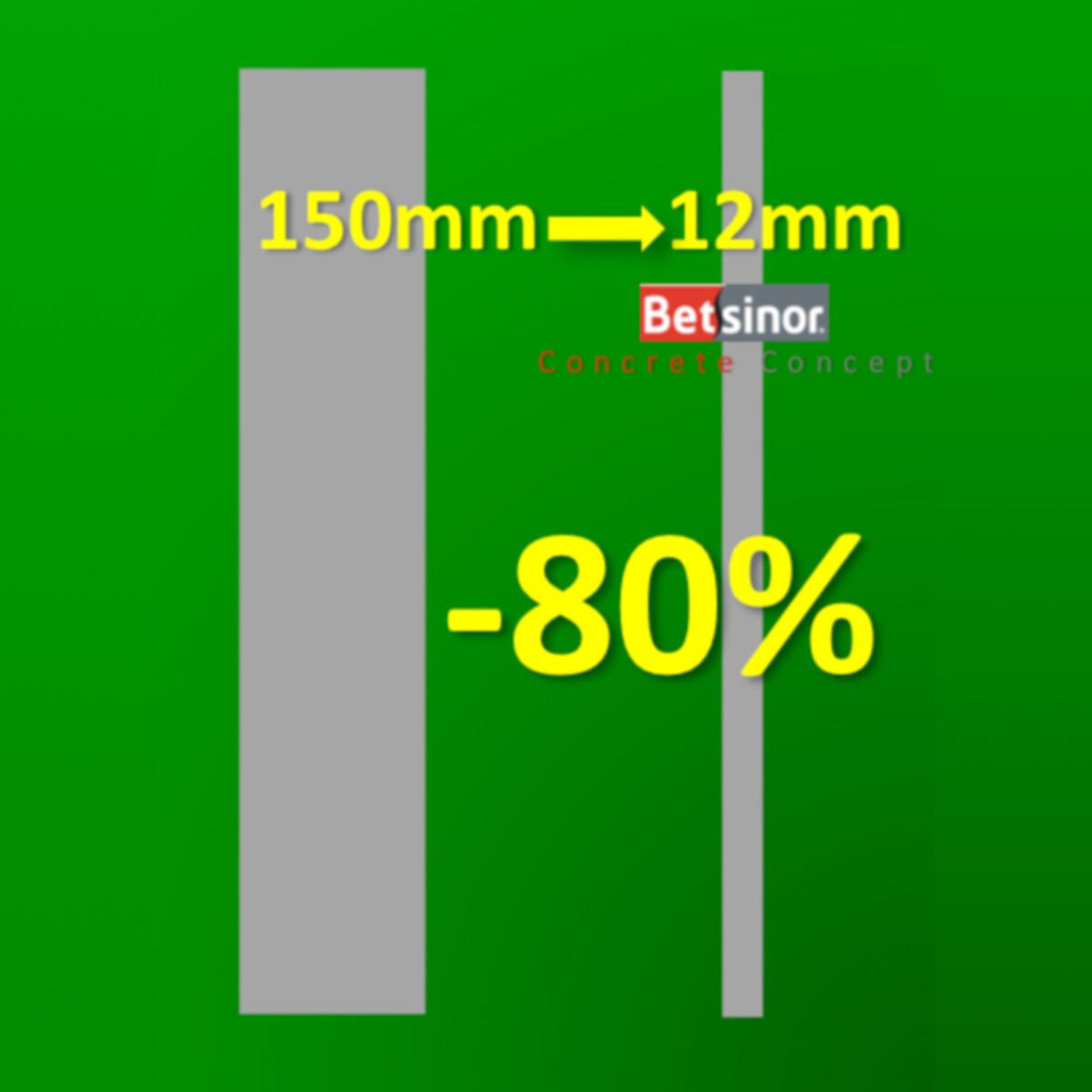

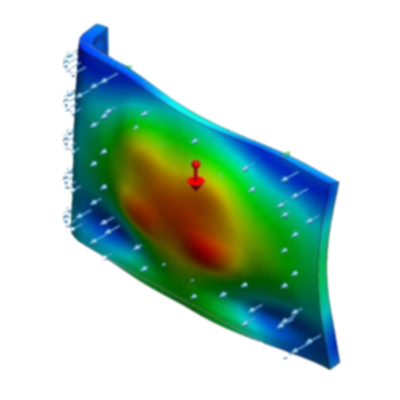

What is the weight of Glassfibre reinforced concrete?

Not less than regular concrete: about 2300 kilo per cubic metre. But the advantage is that, thanks to the absence of steel reinforcement, the panel can be very thin. We do not need additional coverage of the reinforcement bars. The amourphos distribution of the fibres does the rest.

![Lightweight GFRC]()

Lightweight GFRC

-

![Preventable Maintenance]()

Preventable Maintenance

Create lighter, brighter designs using Glass Fiber Reinforced Concrete!

-

![St. Nicklas Sculpture]()

St. Nicklas Sculpture

Specials

More than just Cladding.Simple moulds, no metal reinforcement and extremely high strength are some of the advantages of Glassfibre reinforced concrete. Follow your dreams for other applications also. Table tops, garden furniture, roof caps, retail shops. You bring us the idea, we provide the product.

Even though Groupe SOCAP is a large concern, we still concern ourselves about every client and the smallest details.